|

| |

| WELDING FITTINGS |

|

BUTT-WELDING PROVIDES ADVANTAGES:

(Courtesy of FLOWLINE FITTINGS)

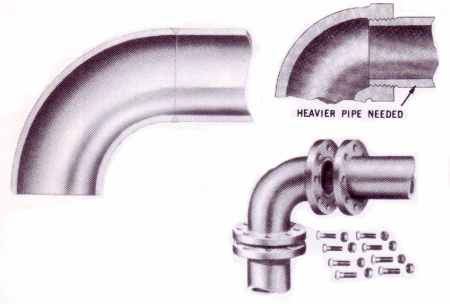

LOWER MATERIAL COSTS

A butt welding assembly uses less

material - a welded joint doesn't requrire extra wall for threading,

or extra material for flanging. |

WEIGHT

A welded elbow connection weighs

approximately one-fourth as much as a flanged connection - an

extremely important consideration when multiplied by the number of

connections in a piping system. The excess weight serves no

useful purpose and places additional strain on the piping system. |

INSULATION

Piping joints can be insulated as

easily as the pipe and fittings. There are no protrusions to

complicate work. Finished system is streamlined and

economical. Leakproof - insulation lasts longer. |

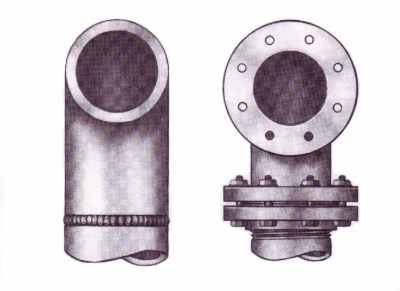

DESIGN

Welded construction permits the

greatest freedom in designing a layout. The system uses less

space: it is more compact, has greater strength. Can be installed

close to wall, ceiling, or floor. |

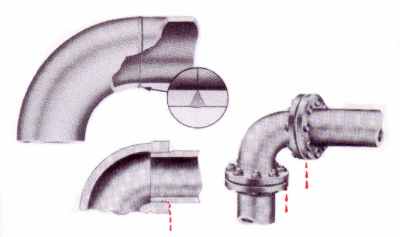

MAINTENANCE AND PLANT SAFETY

Permanently welded - significant to

savings in maintenance and repair costs. No problems with

threading, caulking, gasket replacement and bolt tightening.

Eliminates leaks potentially destructive to equipment and hazardous

to plant personnel. Proven dependability of forged material

for all components. |

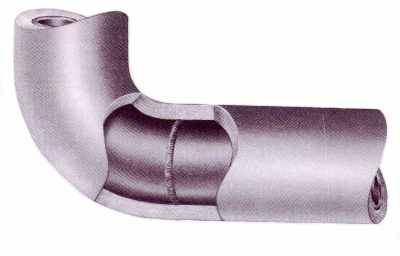

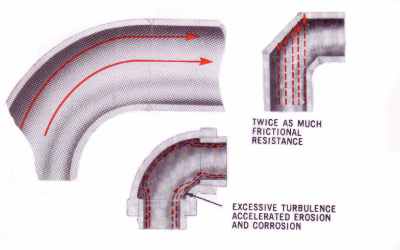

CLEAN...SMOOTH....FULL FLOW

A cleaner system with optimum flow

characteristics. No pockets or sharp corners to cause greater

frictional resistance, pressure loss, turbulence, erosion, and

product accumulation. |

|

|